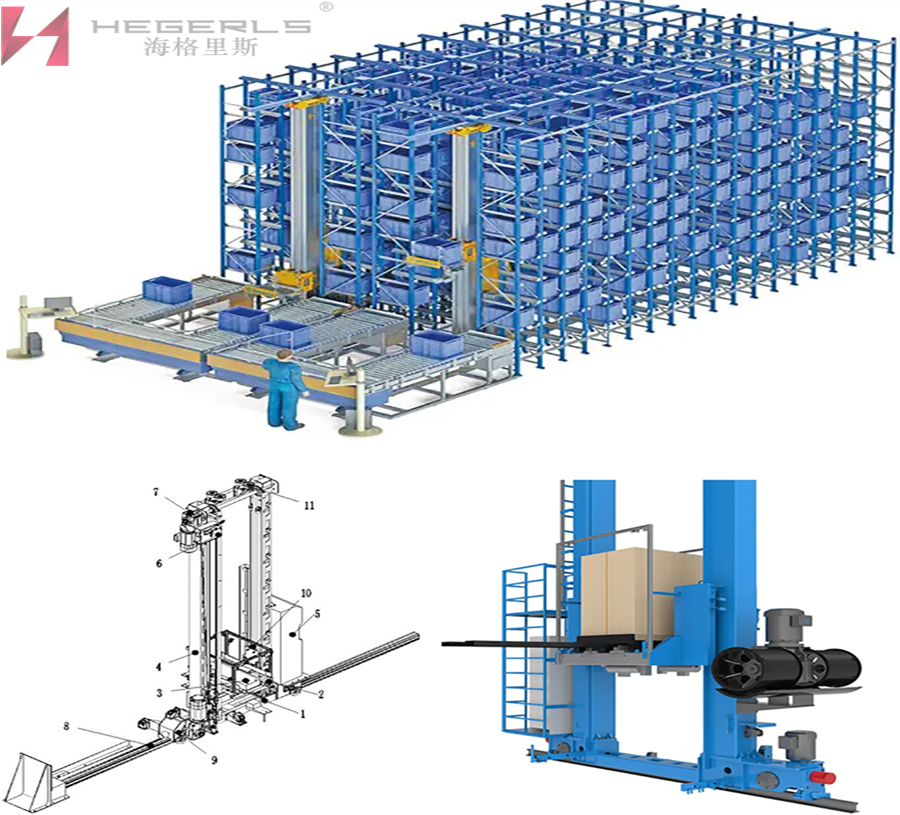

Wurin ajiya na As / RS muhimmin sashi ne na tsarin dabaru na zamani da kuma tsarin ma'auni mai ɗaukaka don ajiya da saye-saye da yawa, gami da tsarin sarrafa sito, shelves, robots, stackers da motocin jigilar kaya.A karkashin tsarin sarrafa na'ura mai kwakwalwa ta WMS, ma'ajiyar na iya gane ajiyar kaya ta atomatik da kuma gane hanyar sadarwa tare da tsarin gudanarwa, wanda ke cikin matakan gudanarwa na zamani.Stacker shine mafi mahimmancin kayan ɗagawa da kayan sufuri a cikin ɗakunan ajiya mai girma uku da alamar da ke wakiltar halayen ɗakunan ajiya mai girma uku.Babban manufarsa ita ce ta yi aiki a cikin tashar sito mai girma uku, adana kayan a layin da ke wucewa cikin grid na kayayyaki, ko fitar da kayan da ke cikin grid na kayayyaki da jigilar su zuwa mashigar titin.

A tsarin abun da ke ciki na stacker hada da: kasa hanya, babba jagora dogo, kaya dandali, aiki panel da kuma dagawa motor, da stacker yana da alaka da babba management tsarin da kuma kula da tsarin don gane aiki da kai na kaya a ciki da kuma wajen sito.An karɓi yanayin sadarwar infrared don stacker da shelf mai girma uku.Babu buƙatar shirya wayoyi masu yawa tsakanin tarurrukan bita, waɗanda ke da ƙarfin hana tsangwama.Microcomputer na guntu guda ɗaya na cikin tsarin sarrafawa na cibiyar aunawa da sarrafawa, wanda zai iya ba da umarnin mayar da martani a kan kari ga kwamfutar gudanarwa ta babba da kuma kafa sadarwa tare da babbar kwamfuta cikin kankanin lokaci.

Hakika, a cikin mahallin m zamantakewa da tattalin arziki ci gaban, Enterprises za su zama mafi damuwa da cewa a karkashin bukatun na high dace, da gargajiya kaya sito ba zai iya cika da bukatun, amma aikace-aikace na stacker a atomatik uku-girma sito taka wani. muhimmiyar rawa.Dangane da wannan, masana'anta na Hercules Hergels ajiya shelf zai mayar da hankali kan matsalolin da suka faru a cikin amfani da stacker, da kuma gabatar da mafita ga waɗannan matsalolin.

Hakika, a cikin mahallin m zamantakewa da tattalin arziki ci gaban, Enterprises za su zama mafi damuwa da cewa a karkashin bukatun na high dace, da gargajiya kaya sito ba zai iya cika da bukatun, amma aikace-aikace na stacker a atomatik uku-girma sito taka wani. muhimmiyar rawa.Dangane da wannan, masana'anta na Hercules Hergels ajiya shelf zai mayar da hankali kan matsalolin da suka faru a cikin amfani da stacker, da kuma gabatar da mafita ga waɗannan matsalolin.

Laifi gama gari da hanyoyin kulawa na stacker

Laifi da rashin daidaituwa na mai sauya mitar kwance a kwance

Lokacin da mai jujjuya mitar a kwance ya gaza, galibi yana faruwa ne saboda ragewa ko tsayawa na stacker da ke haifar da shi (overload, da sauri da sauri, da sauransu).

Maganin kulawa shine: za'a iya mayar da stacker zuwa wurin asali, a cikin rashin kaya da daidaitaccen yanayin tsayawa, sannan sake saitawa.

Kuskuren tsayawa kwance a kwance

Menene rashin kwanciyar hankali a kwance?A wasu kalmomi, yana kasa yin gudu zuwa wurin tsayawa a cikin ƙayyadadden lokaci ko lokuta.

Maganin kulawa shine: yana iya ci gaba da aiki bayan ana iya sake saita shi lokaci-lokaci;Koyaya, idan akwai ci gaba da faruwa, ya zama dole a duba birki mai riƙewa ko waƙa na motar kwance.

Laifi na kwance a kwance

Kuskuren ɓoyayyen ɓoyayyen ɓoye a zahiri yana nufin cewa karatun na kwance ba daidai ba ne.

Maganin kulawa shine: idan lambar matakin ba ta da kyau lokaci-lokaci, ana iya sake saita shi kuma a ci gaba da aiki;Idan akwai ci gaba da faruwa, ya zama dole a duba ko code ɗin ya kwance, sannan a sake gudanar da koyarwa bayan dubawa.

Rashin matakin koyarwa da kuskuren da bai saba ba

Koyarwar a kwance ta kasa, wato, adadin ginshiƙai lokacin isa ƙarshen gaba yayin koyarwa bai dace da matsakaicin ginshiƙin da aka bayar ba.

Maganin kulawa shine maimaita koyarwar ko duba ko adadin ginshiƙan da aka bayar daidai ne.

Laifi da rashin daidaituwa na mai gane adireshin gaba a kwance

Maganin kulawa shine: lokacin da aka sami gazawar mai gano adireshin gaba a kwance, zaku iya duba layin, guntu gane adireshi, maye gurbin canji, da sauransu.

Laifi da rashin daidaituwa na mai gane adireshin baya a kwance

Maganin kulawa shine: lokacin da kuskuren mai gane adireshin baya a kwance ya faru, hakika daidai yake da laifin mai gane adireshin a kwance.Hakanan wajibi ne don bincika kewayawa, guntu gano adireshin, maye gurbin mai canzawa, da sauransu.

Laifin sauya iyaka gudun baya ba daidai ba ne

Maganin kulawa shine: lokacin da madaidaicin iyakar gudu na baya ya kasa, za mu iya duba kewayawa, cire allon haske ko maye gurbin mai canzawa.A lokaci guda kuma, muna buƙatar bincika maɓalli na stacker.

Laifin iyakar saurin gaba ba daidai ba ne

Maganin kiyayewa shine: gazawar na'ura mai sarrafa saurin gaba a zahiri daidai yake da gazawar na'urar ta baya, wato, ya zama dole a duba kewayawa, cire farantin haske ko maye gurbin na'urar, sannan a duba. encoder na stacker.

Laifin canza ƙarshen baya mara al'ada | ƙarancin canjin ƙarshen gaba

Maganin kulawa shine kamar haka: a gaskiya, lokacin da na'urar ta baya ta kasa kuma na gaba ta kasa, maganin kulawa daidai yake da na rashin saurin saurin baya da kuma gazawar gaba.Hakanan wajibi ne don bincika kewayawa, cire farantin haske ko maye gurbin maɓalli, sannan kuma duba maɓalli na stacker.

Laifi na baya na aiki a kwance

Menene laifin baya aiki a kwance?Wato, alkiblar ƙimar bugun bugun bugun bugun zuciya na kwancen bugun bugun jini ya saba wa alkiblar siginar motsi da aka bayar.

Maganin kulawa shine: muna buƙatar bincika ko an haɗa layin A da B na encoder na bugun jini daidai, ko kuma tsarin tsarin samar da wutar lantarki daidai ne.

Laifin ba daidai ba ne bayan mai tari ya koma jirgin ƙasa na ƙarshe

Lokacin da stacker ya ja da baya zuwa ginshiƙi na ƙarshe, wannan al'amari shine saboda aƙalla mai gane adireshi ɗaya a kwance na stacker yana barin ƙarshen ƙarshen adireshin a matsayi na ƙarshe.

Maganin kulawa shine: abin da muke buƙatar yi shine duba birki na kwance a kwance, na'urar gano adireshin, yanki mai gano adireshi, da farantin cire haske na kowane na'urar gano adireshin.

Laifin da ke gaban babban jirgin ƙasa a gaban stacker ba al'ada ba ne

Menene a gaban stacker da gaban mafi girma jirgin kasa?A haƙiƙa, yana nufin cewa aƙalla mai gane adireshi ɗaya a kwance na stacker baya ƙarshen ƙarshen guntun adreshin a sahun gaba.

Maganin kulawa shine: abin da ake buƙatar yi shine duba birki na kwance a kwance, na'urar gano adireshin, yanki na tantance adireshi, da farantin cire haske na kowane na'urar gano adireshin.

Juyar da kuskuren sauya iyaka gudun ba daidai ba ne

Maganin kiyayewa shine: a haƙiƙa, ma'anar ta zahiri ita ma an fahimce ta sosai.Maganin kulawa shine duba kewayawa, allon iyakar gudu da maye gurbin mai sauyawa.

Gudun stacker ya yi ƙasa da ƙasa kuma maras kyau

Laifin ƙananan gudu na stacker ba al'ada ba ne, wato, stacker ba zai iya aiki a wurin ba na dogon lokaci bayan shigar da guntu gano adireshin.

Maganin kulawa shine: lokacin da irin wannan kuskuren ya faru ba daidai ba, abin da ake buƙatar dubawa shine na'ura, waƙa ko ƙara dan ƙara gudun filin ajiye motoci.

Laifi da rashin daidaituwa na mai magana a kwance

A zahiri, an fahimci cewa lokacin da duk wani mai gano adireshin kwance ya gaza ko aiki ta atomatik, stacker ya gudu zuwa jirgin da zai nufa, amma ba a sami yanki a cikin keɓaɓɓen kewayon bugun bugun kuskure ba.

Maganin kulawa shine: lokacin da za'a iya sake saita shi lokaci-lokaci, zai iya ci gaba da gudana;Koyaya, idan akwai ci gaba da faruwa, ya zama dole a bincika ko mai gane adireshin a kwance al'ada ce.

Rashin matakin koyarwa da kuskuren da bai saba ba

Maganin kulawa shine: wato, jimlar adadin ginshiƙan da aka siffanta a kwance ba su dace da adadin ginshiƙan da aka ƙidaya don koyarwa ba.Lokacin da wannan kuskuren ya kasance mara kyau, ya zama dole a duba adadin ginshiƙan da aka ayyana.Matsakaicin ginshiƙi na stacker titin shine ginshiƙai 100 da guntu fitintun adireshi a kwance, kuma ko na'urar tantance adireshin zata iya hango shi.

Bangaren kuskuren ginshiƙin wurin zuwa

Maganin kulawa shine: ma'ana, wurin aiki na stacker bai dace da wanda aka fitar ba.A wannan lokacin, abin da ya kamata a yi shi ne duba adireshin inda za a raba, share aikin da sake rarraba aikin.

Laifin mai sauya mitar tsaye da rashin daidaituwa

Maganin kulawa shine: to mene ne laifin mai canza mitar a tsaye?A haƙiƙa, kariyar mai sauya mitar a tsaye yana faruwa ta hanyar wuce gona da iri ko rage saurin gudu.Maganin da Hercules Hergels ma'aikacin ma'ajiya na ajiya ya bayar shine a mayar da stacker zuwa ainihin ma'ana, a cikin rashin kaya da daidaitaccen yanayin tsayawa, sannan sake saitawa.

Kuskuren tsayawa mara kyau

Maganin kulawa shine: abin da ake kira rashin daidaito tasha a tsaye yana nufin cewa stacker ya zarce adadin da aka kayyade yayin aiki mai saurin gudu da faɗuwa.Kamfanin kera kayan ajiya na Hercules shima ya sami amsa daga abokan cinikin haɗin gwiwa kan wannan matsala mara kyau.Dangane da shekaru masu yawa na gwaninta, masana'antar adana kayan ajiya na Hercules shima yana da mafita ga wannan matsalar.Yana kama da wasu matsalolin da ke sama.Hakazalika, idan ya faru lokaci-lokaci, ana iya sake saita shi kafin a ci gaba;Koyaya, idan wannan kuskuren ya ci gaba da faruwa, ya zama dole a duba motar da ke riƙe da birki ko waƙa a tsaye.

Laifin coding mara kyau

Maganin kulawa shine: wannan kuskuren ba daidai ba ne, wato, bayanan da mai rikodin tsaye ya karanta ba daidai ba ne.Lokacin da wannan rashin daidaituwa ya faru, ko kuma ya faru lokaci-lokaci, ana iya sake saita shi sannan a ci gaba da gudana;Lokacin da wannan yanayin ya ci gaba da faruwa, ya zama dole a duba ko code ɗin ya kwance, sannan a sake koyarwa bayan dubawa.

Rashin koyarwa a tsaye da kuskuren da bai saba ba

Maganin kiyayewa shine: koyarwar tsaye ta kasa, wato, lokacin da koyarwar ta kai ƙarshen babba, adadin yadudduka bai dace da iyakar da aka ba da shi ba;Don wannan al'amari, ƙera hegerls shelf na hagris yana ba da shawarar cewa za a koyar da adadin da aka bayar ko kuma a sake duba shi, kuma ko guntu ɗin tantance adireshin da mai gane adreshin kowane Layer na iya gano shi.

Laifin adireshi na sama (ƙananan | babba) ba daidai ba ne

Maganin kulawa shine: lokacin da wannan kuskuren ya kasance maras kyau, wajibi ne a duba kewaye, cire allon haske ko maye gurbin maɓalli, da kuma duba editan stacker.

Iyakar babban gudun | ƙarancin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun saurin gudu ba su da kyau

Maganin kulawa shine: iyakar gudu na sama da ƙananan madaidaicin maɓalli ba su da kyau, wanda aka fahimta sosai.Maganin shine a duba kewayawa kai tsaye, cire farantin haske ko maye gurbin mai kunnawa.Tabbas, ya kamata kuma a duba mai rikodin ma'auni a lokaci guda.

Laifi na baya na aiki a tsaye

Maganin kulawa shine: wannan kuskuren shine cewa jagorancin ƙimar bugun jini na mai rikodin bugun jini na tsaye ya saba wa jagorancin siginar motsi da aka ba;Yayin kula da shi, ma'aikatan za su bincika ko an haɗa layin A da B na ma'aunin bugun bugun jini daidai, ko kuma tsarin tsarin samar da wutar lantarki daidai ne.

Laifin kariyar da ke kwance igiya na gwamnan gudun ba daidai ba ne

Maganin kulawa shi ne: idan aka sami kuskure a cikin sako-sako da kariyar igiyar mai gudu, a tabbatar da ko igiyar karfen mai gudun ba ta da tushe.Idan haka ne, ma'aikatan suna buƙatar dubawa da gyarawa.

Laifi a ƙarƙashin guntu gano adireshin na mafi ƙanƙanta Layer da mafi girman Layer na pallet ba daidai ba ne

Maganin kulawa shine kamar haka: a zahiri, ƙananan ƙarshen ko babba na yanki na gano adireshin yana bayyana a cikin duka na'urorin gano adireshin a kan dandamalin kaya a ƙasa ko sama.Maganin shine a duba birki na tsaye kai tsaye, na'urar tantance adireshi da yanki na gano adireshi.

Laifin kuskuren wuce gona da iri a tsaye

Maganin kulawa shine: kuskuren da aka ce a tsaye wuce gona da iri ba shi da kyau, wato, ainihin saurin da aka gano ya wuce ƙayyadadden kewayon saurin da aka bayar.Mai sana'ar hegris hegerls ma'ajiyar shelf yana ba da shawarar duba igiyoyin mota a tsaye da riƙon birki.

Bangaren kuskuren mai adireshin tsaye

Maganin kulawa shine kamar haka: Laifin mai gano adireshin a tsaye ba daidai ba ne, wato, lokacin da kowane mai gano adireshin a tsaye ya kasa ko ya yi aiki kai tsaye, pallet ɗin ya gudu zuwa wurin da aka nufa, amma ba a sami yanki a cikin ƙayyadaddun adireshin ba. kewayon bugun bugun kuskure.Abin da kamfanin ya kamata ya yi shi ne duba ko sauyawa da da'ira sun lalace ko kuma guntuwar gano adreshin sun yi aiki tare.

Laifin rotor na kulle cokali mai yatsu ba daidai ba ne

Maganin kulawa shine: ƙila kamfanoni da yawa sun fuskanci wannan matsala ta kuskure, wato, ba a tsawaita cokali mai yatsa a cikin ƙayyadadden lokaci.Lokacin da wannan matsala ta faru, muna buƙatar bincika ko akwai cikas a kan hanyar tsawo na cokali mai yatsa ko kuma ko injin ya ɓace;Lokacin danna maɓallin aikin kore don share kuskure, sannan danna cokali mai yatsa kuma yayi aiki akai-akai har sai cokali mai yatsa ya tsaya daidai.

Babban kuskuren gano cokali mai yatsu mara kyau

Maganin kulawa shine: wato, lokacin da cokali mai yatsa yana da matsayi na tsakiya, aƙalla babban cokali mai yatsa na tsakiya ba shi da sigina, ko babban cokali mai yatsa bai karbi matsayi na tsakiya ba;Idan akwai gazawar na'urar gano cokali mai yatsa na sama, ya zama dole a duba ko sauyawa da kewayawa sun lalace, ko kuma canjin ya dace da mai sarrafa tasiri.A lokaci guda kuma, wajibi ne a bincika ko cokali mai yatsa ya koma matsayinsa na asali.

Laifin sauya tsaka tsaki na cokali mai yatsu ba shi da kyau

Maganin kulawa shine: lokacin da maɓalli na tsakiya na tsakiya ya zama mara kyau, ya zama dole don bincika ko sauyawa da kewayawa sun lalace ko kuma mai canzawa da tasiri sun yi aiki tare.

Binciken hagu na cokali mai yatsu | Laifin sauya binciken dama ba daidai ba ne

Maganin kulawa shine: lokacin da maɓallin gano hagu ko dama na cokali mai yatsa ya kasa, yana nufin cewa hagu ko dama na gano cokali mai yatsa ba zai iya gane kullun ba.A wannan lokacin, abin da ya kamata mu yi shi ne bincika ko sauyawa da kewaye sun lalace ko kuma kai tsaye daidaita kuskuren na'urar ganowa.

Hagu | Dama skew gano kuskuren kuskure

Maganin kulawa shine: lokacin da maɓallin gano skew na hagu na dama ba daidai ba ne, duba ko sauyawa da da'ira sun lalace kuma ko mai kunnawa da na'urar gani sun haɗa kai.

Canjin gano kaya na pallet kuskure ne ko mara kyau

Maganin kulawa shine: lokacin da na'urar gano kayan aiki na dandamalin loading yana da matsala mara kyau, ya zama dole a duba ko sauyawa da kewayawa sun lalace kuma ko maɓalli da na'urar gani sun dace.

Inching rashin kuskuren lokacin ƙarewa

Maganin kulawa shine kamar haka: lokacin da pallet bai tashi zuwa babban matsayi ba lokacin ɗaukar kaya ko kuma bai faɗi zuwa ƙananan matsayi ba lokacin adana kayan a cikin ƙayyadadden lokacin, ma'aikatan ya kamata su fara duba ko sauya mai gane adireshin shine. lalace ko kuma an daidaita maɓalli da mai gano adireshin.

Laifin igiya mara kyau mara kyau

Maganin kulawa shine: lokacin da igiyar wayar karfe ta kwance ko ta karye, duba ko akwai ƙararrawar ƙarya kuma tuntuɓi ma'aikatan goyan bayan fasaha.

Laifin kariya fiye da kima | rashin daidaituwar nauyin kaya superelevation rashin daidaituwa

Maganin kulawa shine: lokacin da kaya suka yi kiba ko matsananciyar girma, wajibi ne a warware kayan kafin su sake gudu.

Laifin dogon kaya mara al'ada

Maganin kulawa shine kamar haka: Laifi na sama da dogayen kaya shine lokacin da stacker ya saki kaya a ƙarshen ƙarshen, zai gano cewa akwai kaya akan na'urar.Lokacin da wannan al'amari ya faru, wajibi ne a cire kayan da suka dace a gaban mai ɗaukar kaya kuma danna maɓallin sake saiti don sake saitawa.

Laifin kariyar zafi mai yaƙar cokali mai yatsa

Maganin kulawa shine: Wannan saboda idan ana sarrafa shi na dogon lokaci ko kuma yayi yawa, zai haifar da kariya ta thermal relay na cokali mai yatsa.Idan wannan ya faru, buɗe majalisar sarrafawa kuma danna jan lamba na "fr" thermal relay.

Laifin yanayin koyarwa ba daidai ba ne

Maganin kulawa shine: lokacin da yanayin koyarwa ya gaza, maganin kulawa shine kashe wuta da sake farawa bayan koyarwa, sannan danna maɓallin sake saiti don magance wannan matsala.

Akwai kuskuren aiki mara kyau yayin farawa

Maganin kulawa shine: akwai aiki yayin farawa, wato, ana riƙe aiki ɗaya bayan rufewa, to yaya za a magance wannan yanayin?Tabbas, zaku iya danna maɓallin aiki don sake saitawa ko share aikin na yanzu.

Laifin babban pallet shiga wurin da bai dace ba ba daidai ba ne

Maganin kulawa shine: abin da ake kira babban pallet yana shiga wurin da ba daidai ba shine cewa aikin yana nuna ƙananan wuri kuma kayan pallet sun yi yawa.A wannan yanayin, wajibi ne a sake fitar da aikin sannan a sake shigar da kayan.

Laifin skew / sama da faɗin kaya mara nauyi

Maganin kulawa shine: kayan sun kasance masu karkatacce ko ultra wide, wanda a zahiri yana nufin skew na kayan pallet.Lokacin da wannan al'amari ya faru, ya zama dole a warware kayan pallet kuma a duba ko canjin ganowa ba shi da kuskure.

Lalacewar lambar makafi ta Stacker

Maganin kulawa shine: abin da ake kira stacker blind code yana nufin cewa na'urar daukar hotan takardu baya duba lambar bar.Shawarar da Hercules Hergels ma'aikacin ma'ajiyar ajiya ya bayar shine a goge maɓallin dubawa sannan a duba lambar mashaya.

Sadarwa marar al'ada tare da na'ura

Maganin kulawa shine: lokacin da aka sami gazawar sadarwa tare da na'ura kuma injin ba zai iya motsawa ba, abu na farko da za a bincika shine ko an haɗa layin.

Babu keɓanta laifin pallet a jerin gwanon aiki

Maganin kulawa shine: wasu kamfanoni na iya fuskantar da gaske cewa babu irin wannan pallet a cikin jerin gwanon aiki.Lokacin da wannan ya faru, za su iya fitar da pallet da farko, sannan su sanya pallet ɗin bayan sun ba da aikin.

Pallet na yanzu yana shiga hanyar da ba daidai ba, kuma laifin ba daidai ba ne

Maganin kulawa shine: lokacin da pallet na yanzu ya shiga hanyar da ba daidai ba kuma ya kasa, yana buƙatar sake saka pallet.

Babu laifi ko rashin daidaituwa a cikin ɗauka

Maganin kulawa shine duba matsayin wurin kaya kai tsaye lokacin da ake ɗauka ko babu akwati.

Bangaren kuskuren ajiya sau biyu

Maganin kulawa shine: lokacin da akwai kuskuren ajiyar kaya biyu, abin da ake buƙatar yi shi ne duba matsayin wurin ko gano maɓalli kai tsaye.

Ayyukan da ba bisa ka'ida ba | keɓanta laifin Layer manufa

Maganin kulawa shine: lokacin da waɗannan yanayi biyu suka faru, abin da muke buƙatar yi shine sake fitar da aikin.

Lambar tire mara kyau, kuskure mara kyau

Maganin kulawa shine: gabaɗaya, idan lambar pallet ɗin da aka bincika ta bambanta da lambar pallet ɗin aiki, ko kuma idan pallet ɗin ba a bincika ba, ana buƙatar sake fitar da aikin.

Lokacin isar da aiki | rashin kuskuren dakatar da gaggawa

Maganin kulawa shine: lokacin da isar da saƙon ke gudana akan kari ko kuma akwai tasha ta gaggawa, danna maɓallin sake saiti kawai.

Gano kuskuren canjin iska

Maganin kulawa shine: lokacin da akwai kuskuren gano canjin iska, ya zama dole don bincika ko sauyawa da kewayawa na al'ada ne.

Pallet a cikin / waje keɓanta laifin rikici

Maganin kulawa shine kamar haka: lokacin da rikici da rashin cin nasara mara kyau na pallet a ciki da waje na sito ya faru, abin da muke buƙatar yi shi ne daidaitawa a ciki da waje na sito.

Laifin girman pallet mara kyau

Maganin kulawa shine: lokacin da girman tire ɗin ya kasance mara kyau, kawai daidaita wurin tire.

Tire mai girman girman hagu | hagu mai nisa

Maganin kulawa shine: lokacin da pallet yana da babban tsayi, babban faɗin hagu da babban faɗin dama, yana buƙatar sake lambar kaya kai tsaye.

Sadarwa marar al'ada tare da stacker

Maganin kulawa shine: lokacin amfani da stacker, za a sami gazawar sadarwa tare da stacker kuma pallet ba zai motsa ba.A wannan lokacin, tsaya kuma duba ko an haɗa layin.

Lokacin aikawa: Mayu-23-2022